PIECES OF ADVICE

Our pieces of advice are simply the expression of our desire to try to explain, in a simple way, to all those in the light rail or tram track business all that we have learned over many years of our rich, sometimes unpleasant experience. Since our company has taken part in the construction and reconstruction of over 100.000 meters of light rail track – very often under the most difficult circumstances in the centers of towns – we feel that we have something to say about this issue. These pieces of advice are dedicated in the first place to the clients since they are in the greatest danger of bringing wrong decisions. They are presented by simplest methods and make only a small part of the light rail track problem area.

WISHES

When a client decides to have light rail track constructed or reconstructed his wishes are simple, but unfortunately very often contradictory. The client wants the track to be: resistant, of a good quality, simple, finished in as short time as possible, without need for maintenance, ecologically positive, esthetically integrated in the surroundings and, of course, low-priced. It is only logical that every bidder claims that his solution is precisely that. To avoid consequent misunderstandings, expenses and disappointments all sides should have basic knowledge of the light rail tracks and primarily of what purpose the track will serve for i.e. how much load it will have to support?

LOAD

It is a frequent occurrence that the light rail load is underestimated and, consequently, the approach to the track construction is similar. That’s a mistake! In spite of the fact that the axle load of a railway vehicle is 2-3 times higher than the axle load of a light rail vehicle, traffic density of the light rail vehicles is much greater, therefore the actual loads on the light rail tracks are also very often heavier than those on the classical railway. Therefore, for the appraisal of the track construction it is important to know the annual tonnage (Gt) – i.e. the quantity of load which is carried over the track in one year. Based on that criterion light rail tracks are divided in four categories. Why is that so important? It is simply because that will determine the longest time period necessary to make some replacement operations on the track. The part which will most certainly wear out and which you will have to replace sooner or later is a rail, and the frequency of its replacement depends on the track category. There is another difficulty with the light rail – the small radius curvatures at which the rail wear is heavy and the rail durability very often extremely low. In the table below there are expressed rail durability values as related to the light rail track category:

|

CATEGORY |

TRAFFIC |

LOAD -Gt- tons/year |

RAIL DURABILITY ON A STRAIGHT LINE (year) |

RAIL DURABILITY IN A CURVATION R<50 m (year) |

|

1 |

low |

Gt < 2.000.000 |

30 - 40 |

10 |

|

2 |

medium |

2.000.000 < Gt < 5.000.000 |

20 - 30 |

5 - 10 |

|

3 |

heavy |

5.000.000 < Gt < 10.000.000 |

20 |

3 - 5 |

|

4 |

extreme |

Gt > 10.000.000 |

< 20 |

2 - 3 |

The replacement of a deteriorated rail is unavoidable but it makes difference under which conditions and how often it will be done and whether there is a probability that some measures will have to be taken even before the replacement of the rails. Those questions bring us directly to the choice of criterion for the light rail track construction.

BASIC CHOICE OF THE LIGHT RAIL TRACK CONSTRUCTION

Every track maintenance operation represents expenditure and a problem! Advice: Avoid using constructions on a crashed stone surfacing whether there are sleepers or rails are directly laid on the crushed stone. Why? Such constructions involve intensive maintenance or else they become unstable. As the basic truck construction choose some kind of concrete or reinforced concrete foundation laid on a layer of cohesionless material. It is advisable that the foundation be as thick as possible since it has good effect on vibrations propagation.

BASIC CHOICE OF MATERIAL

When talking about the choice of material we primarily think about some kind of levelling base course between the rail and the concrete foundation. There are many different materials in use today but, in our opinion, only three of those are of adequate quality: Polyester, Epoxid and Polyurethane. Avoid bitumen based materials because they haven’t proved to be resistant to heavier loads.

THE DEGREE OF THE TRACK CONSTRUCTION DEMOUNTABILITY

Light rail tracks are mostly located in cities; they pass through densely populated zones and are very often integrated into the city road network. Such a location of rail track because of daily traffic in most cases requires that the work on the track be done only during one part of night and it is opposed to the minimum noise requirements. Owing to that, works on the light rail maintenance are extremely specific, expensive and are done under great pressure. This problem brings us to a very important issue and that is the degree of the track construction demountability.

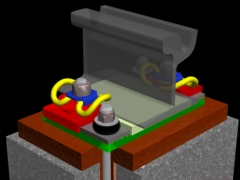

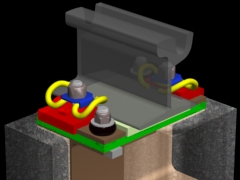

The construction demountability degree is defined by the ratio of the parts which can be reused after their demounting and the total number of integral parts of the construction and it is somewhere between 0 < Fr < 1. Concrete and reinforced-concrete foundations are not included in the calculus of the demountability. In the figures below there are illustrations of two constructions with their demountability degrees:

Fr = 0 Fr = 0.88

The demountability degree - Fr - is of an extreme importance. - Fr - value being lower, the costs, work duration, noise problems and the work complexity are higher. Fr = 0 value means that any intervention on such a construction leads to its demolition and rebuilding of the whole construction. It is obvious that one should aim at a construction with as high - Fr - value as possible. Advice: Choose a construction with as high - Fr –value as possible.

REDUCTION DEGREE

At track construction biddings, the distortion value of a rail under load is often presented as one of the arguments regarding its quality. Very often even that information is missing and the construction is simply defined a "elastic". That is not enough! The first task of any track construction is vehicle load transfer and its distribution on the ground. The way this distribution is carried out in the space between the rail top and the concrete foundation plate is of high importance because of the following basic engineering logic: The lower is the force the higher is the construction durability. If the rail is supported by individual bearings the reduction degree - Fq – is defined by the ratio of the force acting upon the rail and the force acting upon the concrete foundation plate in the same segment. There is a whole range of methods for determining the reduction degree but we are presenting the simplest yet good enough for comparison.

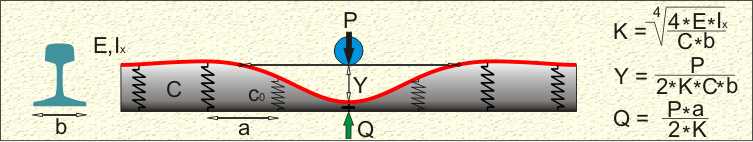

The principle is that an infinitely long rail with the foot width "b" [mm] and "E" [N/mm2], "Ix" [mm4], characteristics, supported by individual bearings with the spring rate "c0" [N/mm] and at a distance "a" [mm] be placed on a uniform medium with the elastic characteristic "C = c0 * a * b" [N/mm3] and burdened with the external force "P" [N]. In that case the deformity "Y" [mm] and the reactive force "Q" [N] are easy to calculate using the expression in the figure.

Reduction degree is calculated from the Fq = P/Q = (2*k) / a ration. Advice: Choose constructions with as high reduction degree - Fq – as possible because they will last longer and the maintenance costs will be lower.

Certain difficulties can arise when determining elastic characteristics of the medium "C" because light rail track elasticity can only be achieved by use of elastomer; therefore something should be said about that too.

FEATURES OF ELASTOMER

By elastomer is meant any material containing a combination of a spring and viscous shock-absorber, and the elasticity is achieved by its form transformation, i.e. if its form transformation (side expansion) is made impossible elastomer will behave as solid material. Determining of a real elastic feature of elastomer is a complex process but, even for that, there is an approximate method which gives quite good results. According to that method elastic feature depends on the elastomer shape "S" and its hardness "H [Sh]". Factor "S" is a dimensionless number and it is called shape factor, and its value for a rectangular shape is defined as expressed in the figure below. In the same figure there has been given expression for the spring rate "Co [N/mm]" of the rectangular elastomer which depends on the shear modulus "G [N/mm2]" of the elastomer. The approximate ratio of "G [N/mm2]" and "H [Sh]" is presented in the diagram.

From the above expressions there can be drawn some conclusions about the application of elastomer. By increasing the length of elastomer "l" the spring rate "Co" will also increase and the distortion "Y" will be lower. The extreme case of such an increase is a rail placed on the elastomeric tape. To achieve the same distortion for the same force the elastomer in form of a tape must have lower hardness "H" as opposed to the rectangular elastomers in individual bearings. The softer is the elastomer, the lower is its resistance to wear. Such a conclusion, along with the fact about the big quantity of elastomer that must be used can, at the evaluation of the construction on the elastomer in form of a tape, seriously prevail in favor of the construction on individual bearings. By shortening the length of elastomer "l", the spring rate "Co" is decreasing, but while at it one should take into account the allowable stresses which are dependent on hardness "H". The approximate distortion value, which should not be over " 0.12*t ", is accepted as sufficient for the stress evaluation.

CONSTRUCTION METHODS

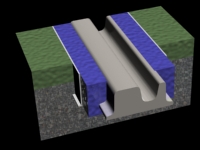

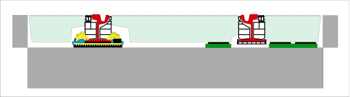

For most light rail track structures there are two methods of construction: Direct (1) and Inverse (2). Both methods are shown in the pictures below.

(1) (2)

Direct method (1) implies pre-construction of a concrete foundation which is followed by fixation of rails for the foundation with the rail fastenings and levelling, load-carrying layer. Inverse method (2) implies that the rail firstly be laid by height and direction on temporary supports and that the rail fastenings be "suspended" on the rail. Only after that the concrete foundation is constructed in a way that the rail fastenings are embedded in it. No matter which method of construction you apply, the rail track structure will in the end have much the same characteristics. Advice : Apply inverse method whenever you can because you will save at least 10% of your money and the construction time will be shorter.

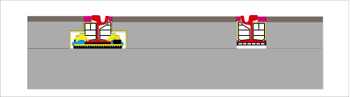

METHODS OF TRACK PAVING

As opposed to classical railroad, light rail tracks are rarely open and that represents an additional difficulty in maintenance, especially when road traffic runs over the track structure. Paving constructions can be divided in two basic groups:

1. Constructions within the road systems over which runs road traffic

2. Constructions separated from the road. This group mostly implies paving with a layer of crushed stone or making of a grass layer

Constructions belonging to the group 2. are simpler and of no special interest although it should be well known that grass surfaced track is the best noise protection. Advice: Apply grass tracks whenever you can!

Constructions belonging to the group 1. are far more complex and therefore need more attention. Because of the differences in deformations of pavement and of the rail track constructions, the rail must be free in its action and must not transmit stress to the track construction or else it will destroy it. For the same reasons as with the rail track construction, group 1 pavement constructions are divided in two subgroups, based on the demountability criterion.

1. Demountable paving constructions 2. Non-demountable paving constructions

Non-demountable constructions are simpler and cheaper in the beginning but, having in mind that every operation on the track involves its demolition, in the end they are often more expensive and represent a problem in the rail track maintenance process. Demountable pavement constructions are more expensive and more complex in the beginning but their elements can be used recurrently and the sole process of their demounting is relatively quick and simple and therefore they are appropriate from the maintenance point of view. They are mostly made of stone or concrete elements placed in-between and on the sides of the rails and their size varies. It has been proved that the optimal size of the elements is cca. 0.5 - 1 m2. Advice: Apply demountable track pavement construction whenever you can.